Most commonly used cabinet materials in the United States

🌕Solid Wood / Solid Wood

🌕Solid Wood / Solid Wood

Solid wood is one of the most popular materials for kitchen cabinets, it is natural, carved and painted.

✅Advantages

Durable

Long life

Easily customize cabinet door styles

Can be restrained or painted to change the appearance

❌Disadvantages

High cost and high maintenance

Some types are prone to warping or shrinking and expanding

May fade or darken due to light

Need to sand and primer to repair solid wood

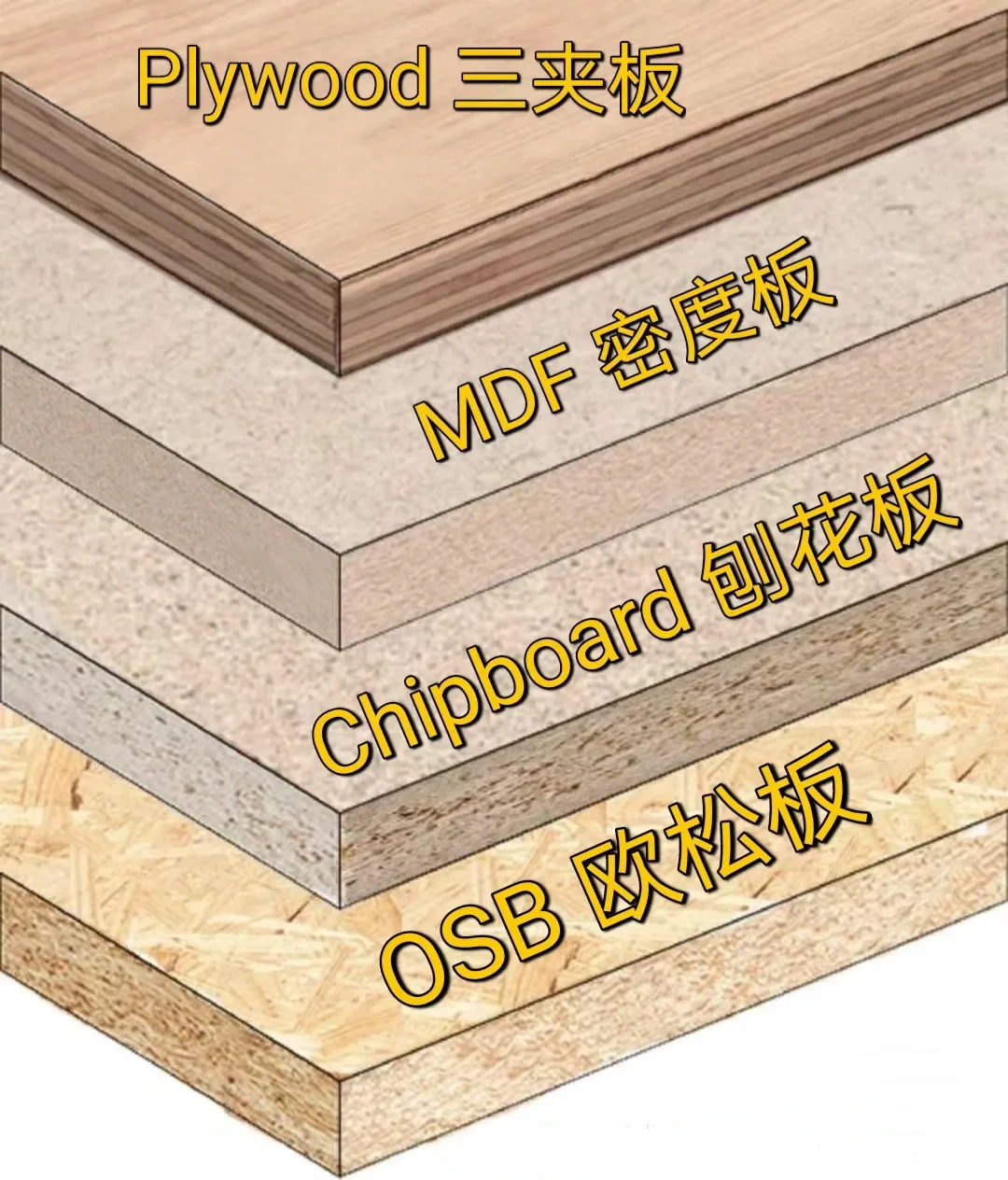

🌕Plywood / Added layer board / Multilayer board

Vinyl wood + glue

It consists of layers of thinly sliced wood (flitches), layered in opposite directions and bonded together with adhesive. Plywood is often covered with decorative wood veneer to give the cabinet box the appearance of wood. It is the strongest of engineered wood, making it the best choice for cabinet boxes, drawer floors, shelves and frames.

✅Advantages

High strength

Strong stability

Reasonable nail holding ability

Affordable price

❌Disadvantages

More expensive than other engineered woods

Not as flat as particleboard and OSB

Not as strong as solid wood

Low-quality plywood can easily break down and fragment

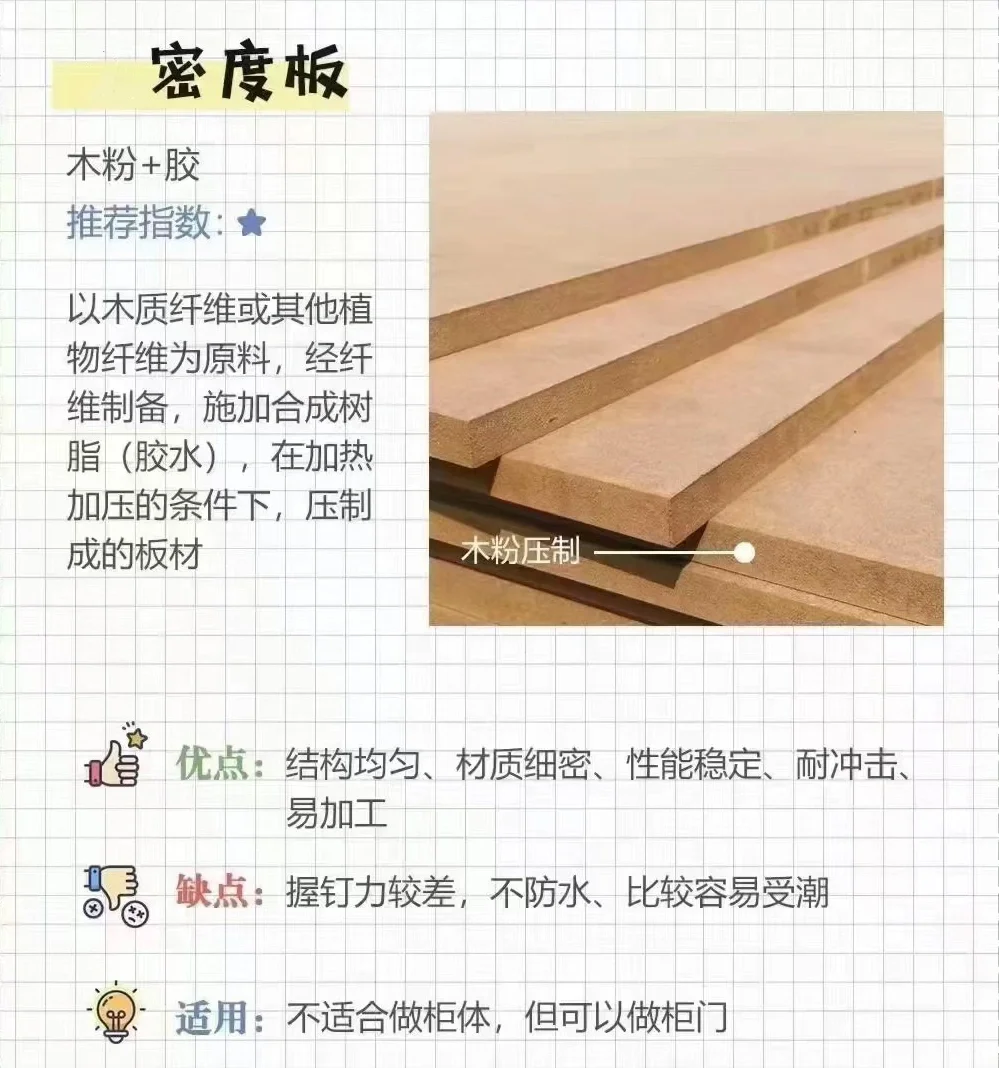

🌕HDF/ MDF/ Density Fiberboard

Using wood fiber or other plant fiber as raw materials, after fiber preparation, applying synthetic resin (glue), and pressing it under heating and pressure to form a board.

✅Advantages

The most affordable type of engineered wood

Easily designed into the desired style

Easy to paint and relatively light

❌Disadvantages

Cannot fix screws or nails

Cannot be sanded

Sensitive to high temperatures

Warp and expand when wet

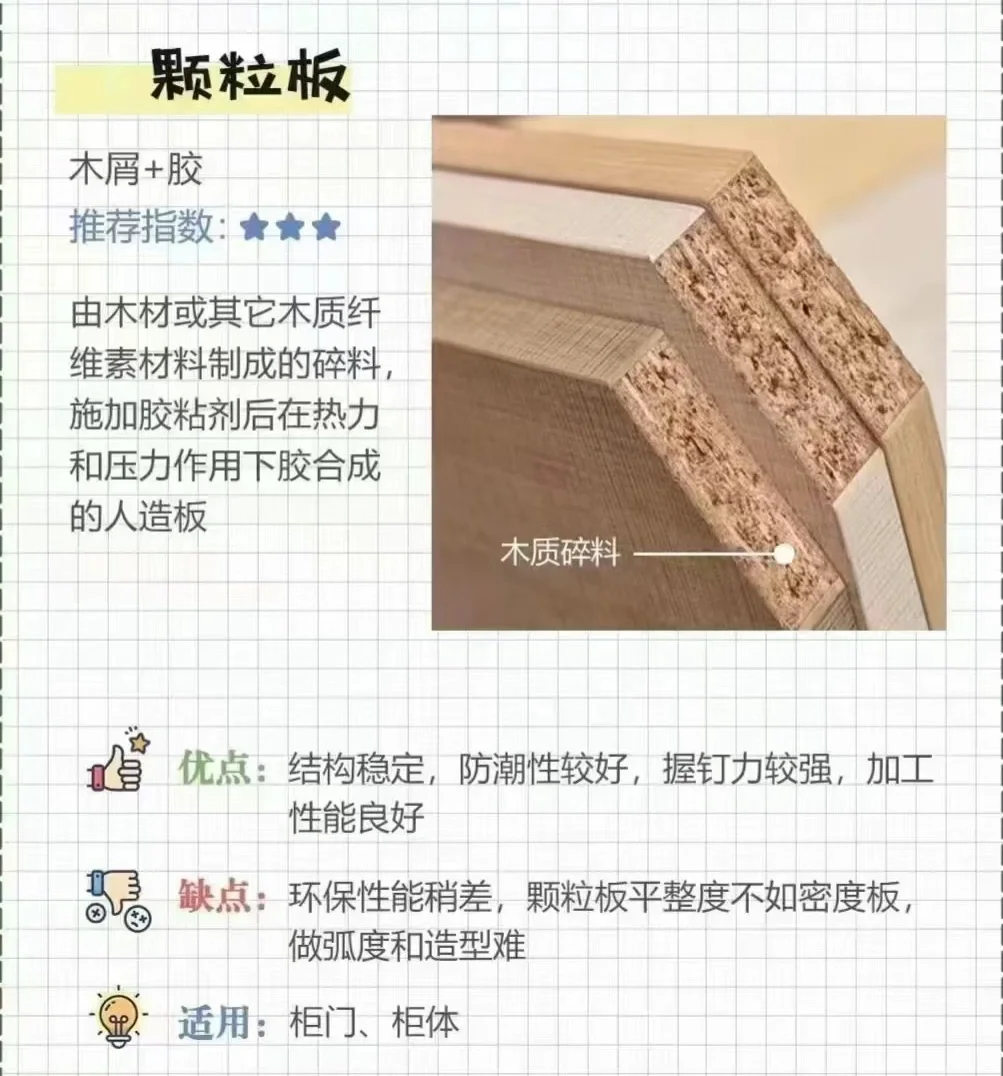

🌕Particleboard/ Chipboard/ Particleboard

Particleboard is a low-density fiberboard made by pressing wood particles (sawdust, wood chips, etc.) into a heated board with resin (glue). It is usually topped with veneer or laminate to create a finished cabinet look.

✅Advantages

Cheap price

Appearance diversity

❌Disadvantages

The least durable wood product for cabinets

Will dent under heavy basin countertops or electrical appliances

Easy to crack or break and not moisture-resistant

🌕OSB/ European Pine Board

The upper and lower surface layers arrange the glue-mixed shavings longitudinally according to their fiber direction, while the core layer shavings are arranged horizontally to form a three-layer structural board embryo with a regular internal structure rather than a scattered directional structure.

✅Advantages

Stable structure

No deformation Good nail holding ability

Good processing performance, waterproof and moisture-proof

High cost performance

❌Disadvantages

The price is higher than particle board

🌕Laminate / Melamine/ Laminated board

Melamine is not a board, it is just a type of lamination, that is, Melamine is pasted on the board. Many melamines on the market are pasted on MDF/HDF or Chipboard, which are called melamine board. Laminated board is a resin combined with paper with the desired design, color or pattern, and pressed together with heat. It is a surface material on plywood or other fiberboard attached to the body of the cabinet.

✅Advantages

Cheap

Easy to clean

Resistant to scratches and stains

Resistant to heat and moisture

Resistant to warping and ripples

❌Disadvantages

If cut or cracked, it cannot be repaired

Quick View

You can check what you need

Copyright © 2023 E&R Wood Co,.Ltd All Rights Reserved. Powered By: www.300.cn SEO

Factory: Zhouwei Village,Yanggongzhou,Shatian Town,Dongguan City,China

Factory: Zhouwei Village,Yanggongzhou,Shatian Town,Dongguan City,China