An article takes you into the world of natural veneer

🟤Definition of natural veneer

🟤Definition of natural veneer

Natural veneer, also known as solid wood veneer and natural thin wood, is made by steaming the logs and then cutting them into thin wood slices with a thickness of usually 0.2~1.0 mm through planing or peeling (imported veneer is usually thicker than 0.5 mm).

It retains the natural texture, color and texture of the wood, and is widely used in furniture manufacturing, interior decoration, wooden doors, musical instruments and other fields. It is a high-end decorative material that is both beautiful and environmentally friendly.

——

🟤Production process of natural veneer

The production of natural veneer mainly relies on two processes:

▪️Planing process: Fix the logs on the planer and cut along the direction of the wood grain. The veneer texture is clear and natural, which is suitable for high-end furniture and decorative veneers.

▪️Pearl cutting process: Fix the logs on the peeling machine and rotate and cut them to form a continuous veneer roll, which is suitable for producing veneer with uniform texture and is often used for artificial board veneer.

▪️After cutting, the veneer needs to go through drying, trimming, dyeing (optional) and other processes to improve stability and beauty.

——

🟤Types of natural veneer

There are many types of natural veneer, which mainly depend on the type of wood and the cutting method. Common ones are:

▪️Classified by tree species: walnut veneer, oak veneer, cherry veneer, maple veneer, teak veneer, etc. Different tree species present different textures and colors.

▪️Classified by cutting method: quarter-cut veneer (straight and uniform texture), tangential-cut veneer (mountain-shaped or wavy), rotary-cut veneer (continuous but ordinary texture).

——

🟤Characteristics and advantages of natural veneer

▪️Natural beauty: The natural texture and color of the wood are retained, and each piece of veneer is unique.

▪️Environmental protection and energy saving: Compared with solid wood, veneer saves more wood resources and conforms to the concept of sustainable development.

▪️Wide range of application: It can be used for furniture, walls, ceilings, wooden doors, car interiors, etc. to improve the grade of products.

▪️Good processing performance: easy to dye and splice, and can create a variety of decorative effects.

——

🟤Application of natural veneer

Natural veneer is widely used in the fields of furniture and decoration, for example:

▪️Furniture veneer: used for surface decoration of high-end solid wood furniture or panel furniture.

▪️Interior decoration: as a finishing material for walls, cabinets, and doors, to enhance the texture of space?

▪️Musical instrument manufacturing: surface decoration of musical instruments such as pianos and guitars.

▪️Automotive interior: Some luxury models use natural veneer to enhance the grade of interior.

▪️Wooden crafts: using the unique texture characteristics of wood to create wooden crafts with unique natural beauty.

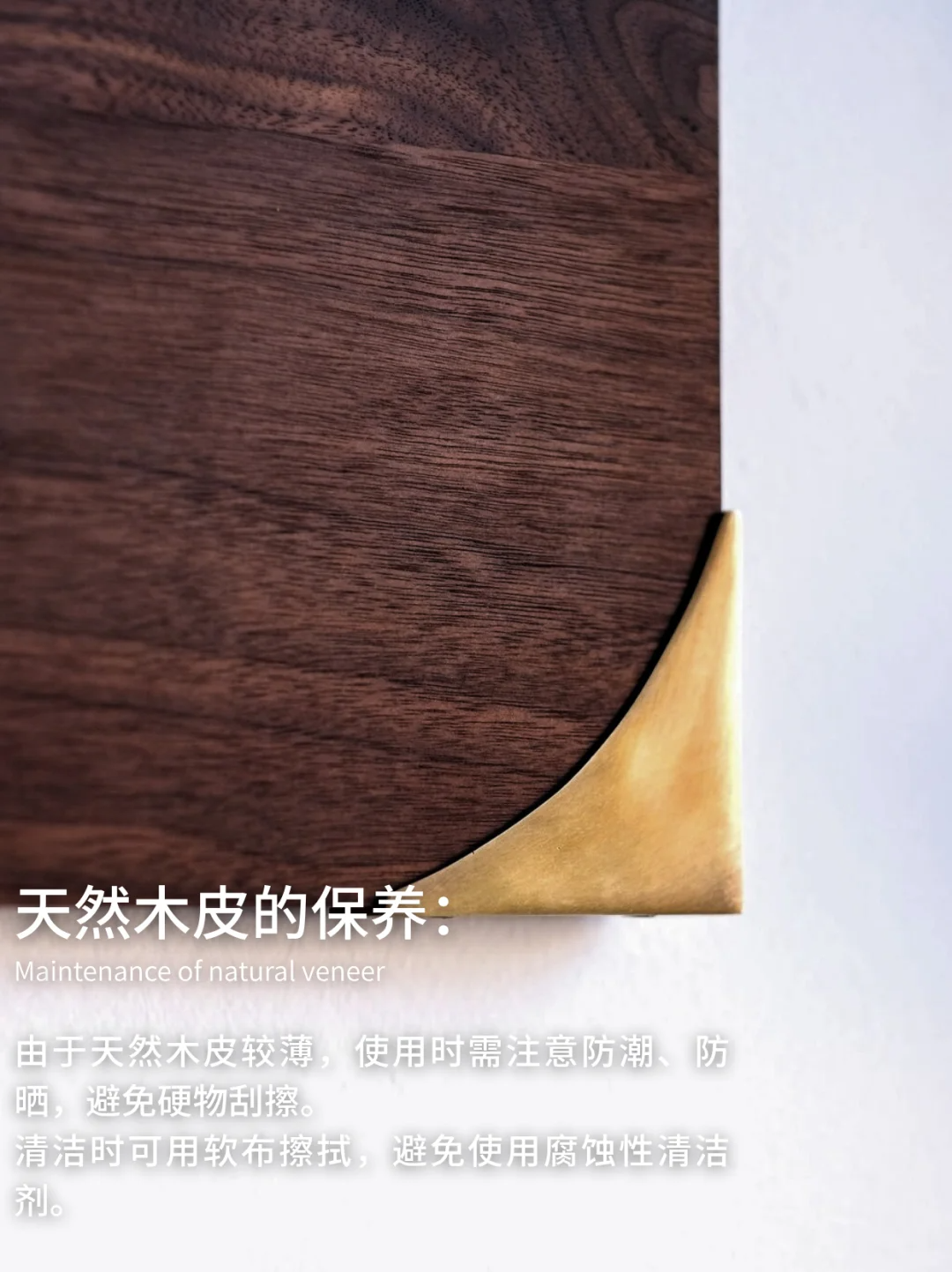

🟤Maintenance of natural veneer

Since natural veneer is thin, it is necessary to pay attention to moisture and sun protection when using it, and avoid scratches from hard objects.

When cleaning, wipe with a soft cloth and avoid using corrosive detergents.

🟤Conclusion

Natural veneer has become an important material for modern decoration and furniture manufacturing with its natural, environmentally friendly and high-end characteristics.

It not only shows the natural beauty of wood, but also conforms to the trend of green and sustainable development. It is an ideal choice for those who pursue quality life.

Pre

Quick View

You can check what you need

Copyright © 2023 E&R Wood Co,.Ltd All Rights Reserved. Powered By: www.300.cn SEO

Factory: Zhouwei Village,Yanggongzhou,Shatian Town,Dongguan City,China

Factory: Zhouwei Village,Yanggongzhou,Shatian Town,Dongguan City,China