So, how is natural veneer produced?

🌳The production process of natural veneer directly impacts its aesthetics and practicality. High-quality veneer requires a balance of raw material selection, meticulous processing, and strict quality control.

🌳The production process of natural veneer directly impacts its aesthetics and practicality. High-quality veneer requires a balance of raw material selection, meticulous processing, and strict quality control.

——

✂️The veneer production process can be summarized as follows:

① Obtaining the raw material, ② Steaming, ③ Slicing, ④ Drying, ⑤ Cutting.

——

💫A brief overview of each process:

▪️ Preparing the log

Whether a piece of wood can be processed into veneer depends on an assessment of its properties: straightness, core and cracking, the presence of visible defects (such as mineral lines, tiger stripes, insect holes, and decay), size, color and stability, grain, and appearance. To meet today's quality standards, the veneer surface should be as defect-free as possible, with a uniform color and texture.

▪️ Steaming

After unloading, the veneer panels may be steamed or not, depending on the situation. Exceptions are made for species where a light-colored or white veneer is desired, such as European maple or white beech. Steaming with hot water produces two effects: (1) The wood acquires the necessary softness and stability to ensure smooth planing. (2) The color of the veneer is affected by the cooking time. For example, beech wood, which is originally white, will turn pink or salmon after steaming. Depending on the tree species and the color requirements, the cooking period varies from 1 to 7 days. Different woods have different cooking periods and cooking temperatures, and this rule must be strictly and accurately followed to avoid color defects. Since the quality of water (hardness, chemical composition) plays a significant role in the wood cooking process, each veneer manufacturer has developed its own most suitable cooking time and temperature standards, which is one of the reasons why the color of the same veneer from different veneer manufacturers can be slightly different. ▪️ Planing There are many different ways to plane wood, and the resulting veneer surface effects are also different. Therefore, the processor must conduct a comprehensive and technical assessment of the expected quality and potential use of the logs. This is an indispensable technical basis for obtaining high-quality veneer in the further processing process. During slicing, the veneer is sliced on one or both sides, ensuring it is perfectly flat and secured to the cutting jig to prevent uneven thickness.

▪️Drying

In modern veneer production plants, moist veneer is dried in a high-speed, air-jet dryer with a conveyor belt, which flattens the veneer.

Different wood types require different drying methods, and the conveyor belt speed and oven temperature must be strictly adhered to. Overdry veneer can crumble, while too damp veneer can mold and become unusable.

Due to the varying densities of different wood components, the veneer may still be warped after drying, so it must be flattened by extensive pressing beforehand.

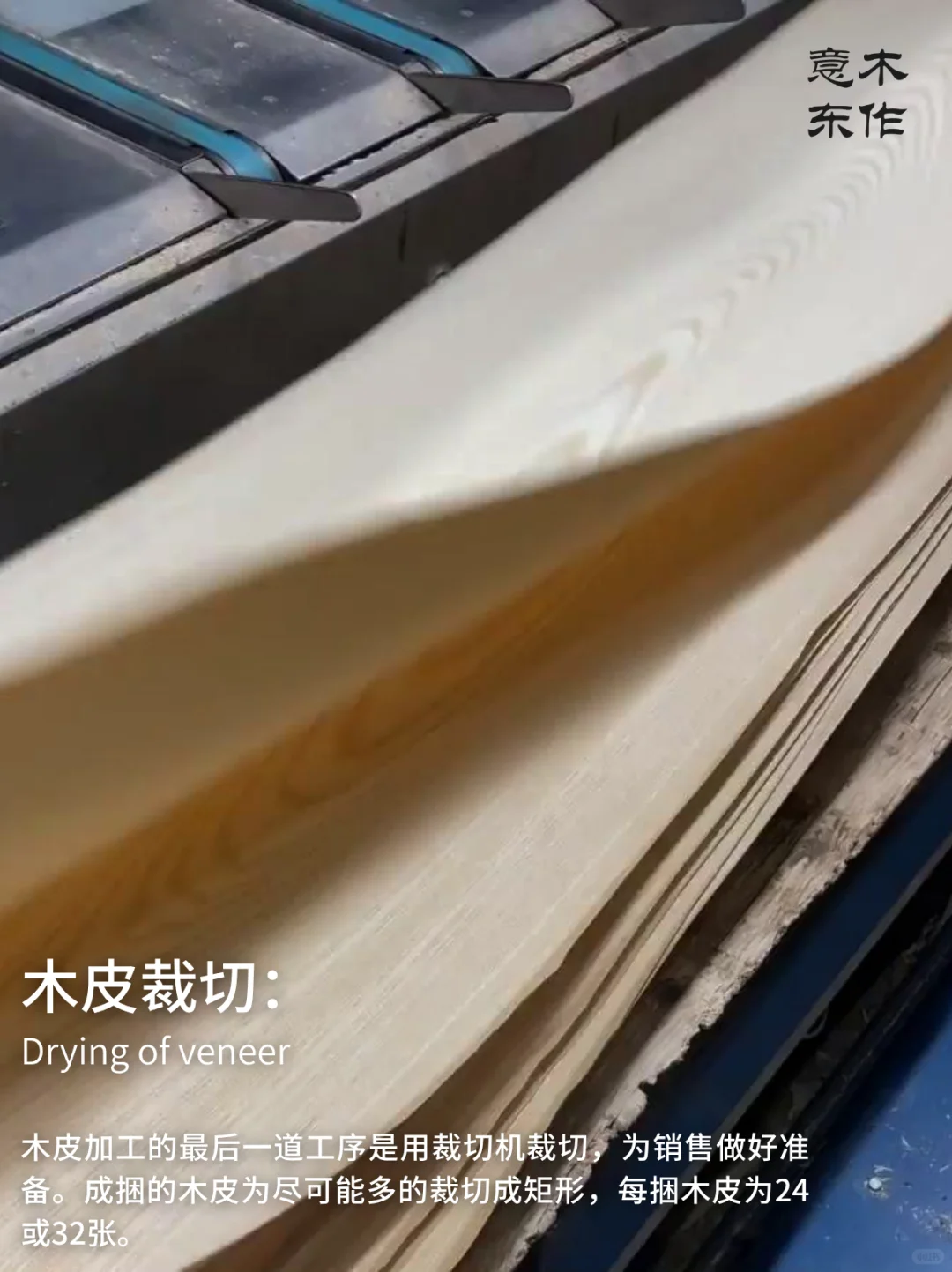

▪️Cutting

The final step in veneer processing is cutting the veneer using a cutting machine to prepare it for sale. The bundles of veneer are cut into as many rectangular pieces as possible, with each bundle containing 24 or 32 sheets.

——

Finally, after processing, piecing, and pressing, it becomes a beautiful wood veneer or furniture piece.

Quick View

You can check what you need

Copyright © 2023 E&R Wood Co,.Ltd All Rights Reserved. Powered By: www.300.cn SEO

Factory: Zhouwei Village,Yanggongzhou,Shatian Town,Dongguan City,China

Factory: Zhouwei Village,Yanggongzhou,Shatian Town,Dongguan City,China