Dyed veneer

The base material of dyed veneer is also natural veneer, and its process is material selection-bleaching and fading-immersion in fuel-fixing-drying-hot pressing-cutting.

The base material of dyed veneer is also natural veneer, and its process is material selection-bleaching and fading-immersion in fuel-fixing-drying-hot pressing-cutting.

We can also understand the whole process as the same as dyeing cloth.

Of course, some veneers cannot be dyed because of the problem of fading.

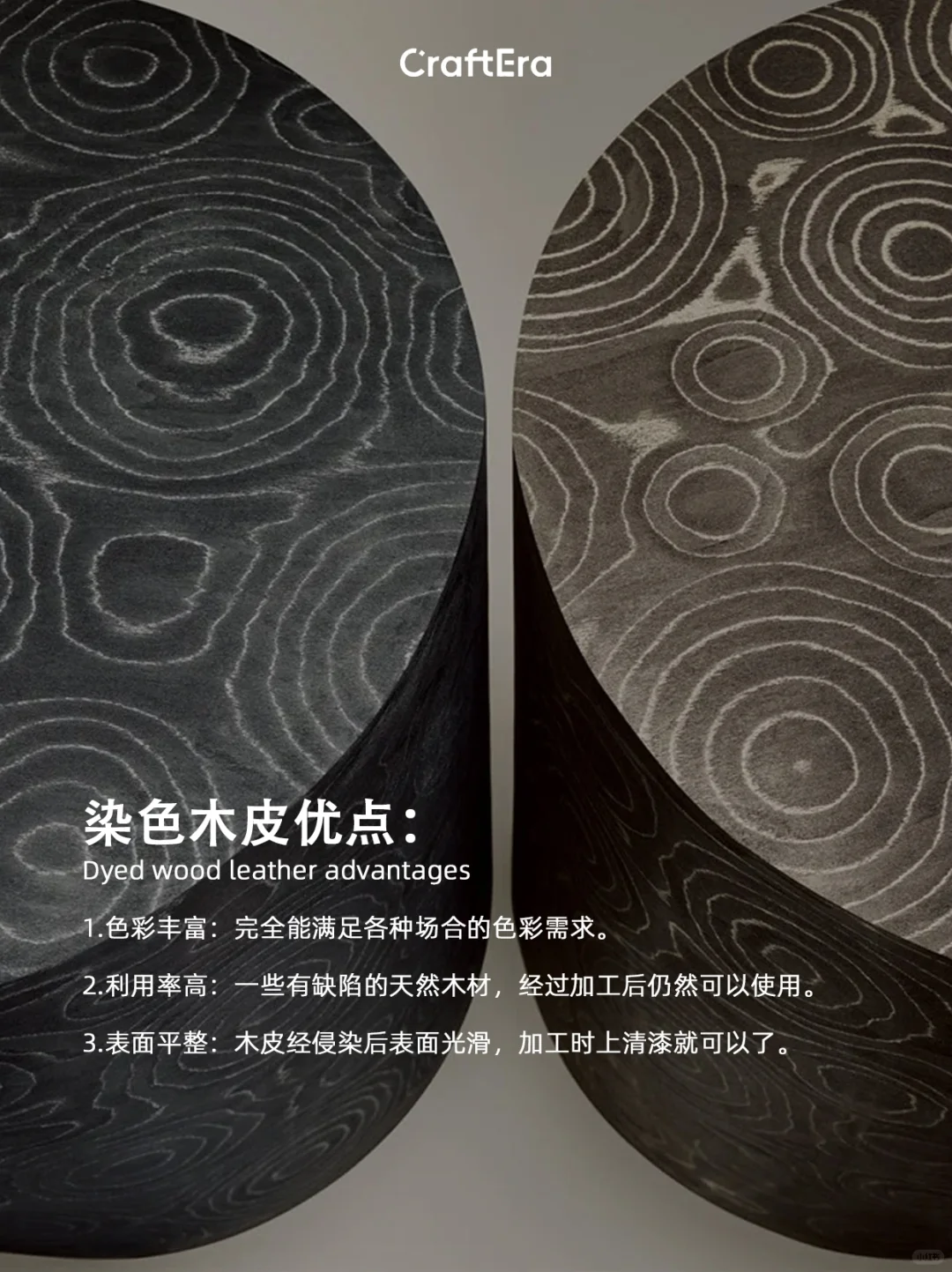

Advantages of dyed veneer

1⃣️ Rich colors: can fully meet the color requirements of various occasions.

2⃣️. High utilization rate: some defective natural wood can still be used after processing.

3⃣️ Smooth surface: The surface of the veneer is smooth after infection, and varnish can be applied during processing.

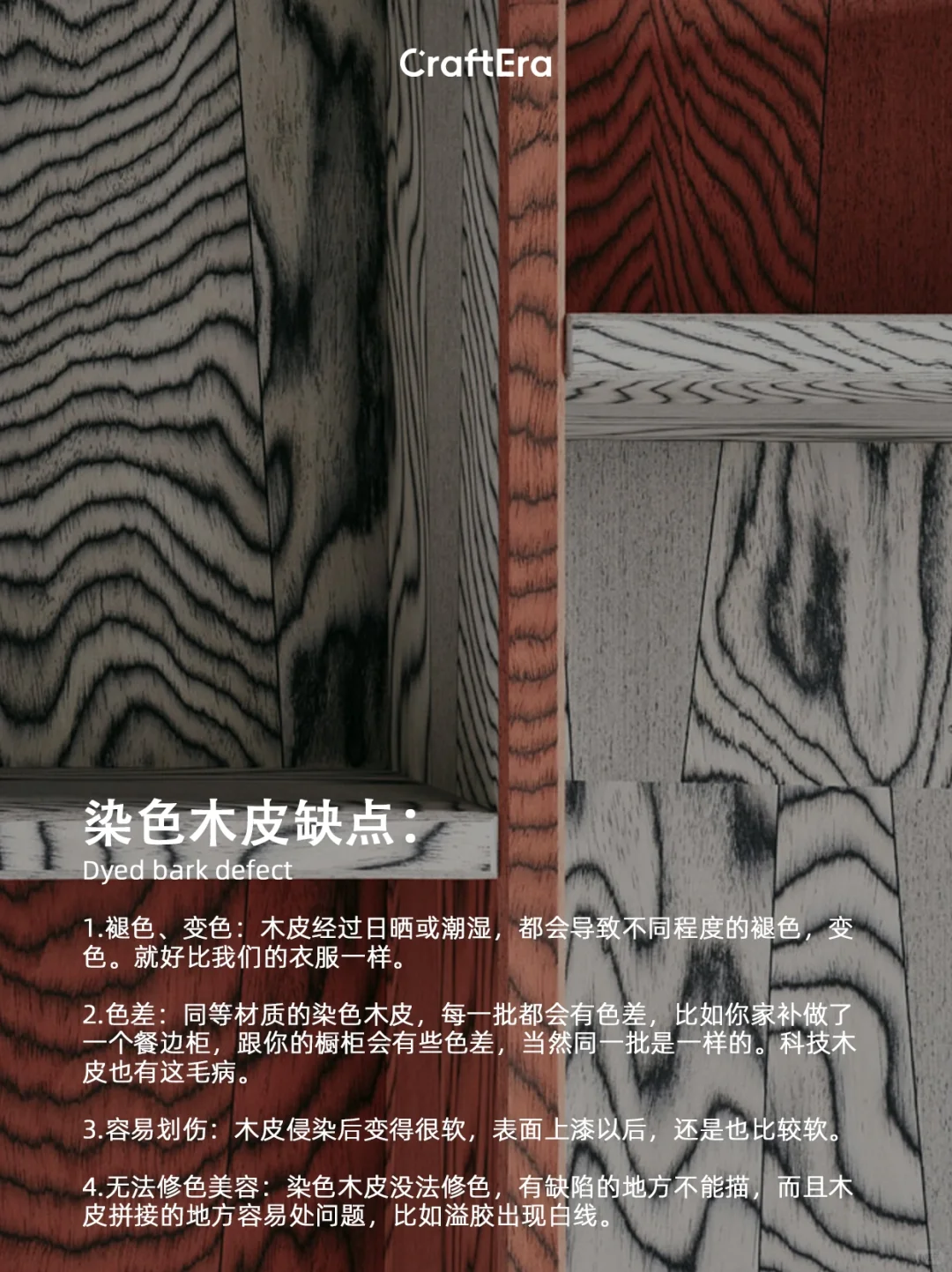

Disadvantages of dyed veneer

1⃣️ Fading and discoloration: The veneer will fade and discolor to varying degrees after being exposed to the sun or moisture. Just like our clothes.

2⃣️Color difference: Each batch of dyed veneer of the same material will have color difference. For example, if you make a sideboard at home, it will have some color difference with your cabinet, of course, it is the same in the same batch. Technical veneer also has this problem.

3⃣️Easy to scratch: The veneer becomes very soft after being infected, and it is still relatively soft after being painted on the surface.

4⃣️Cannot be repaired and beautified: Dyed veneer cannot be repaired, and the defective areas cannot be traced. In addition, the joints of the veneer are prone to problems, such as white lines due to overflow of glue.

Quick View

You can check what you need

Copyright © 2023 E&R Wood Co,.Ltd All Rights Reserved. Powered By: www.300.cn SEO

Factory: Zhouwei Village,Yanggongzhou,Shatian Town,Dongguan City,China

Factory: Zhouwei Village,Yanggongzhou,Shatian Town,Dongguan City,China